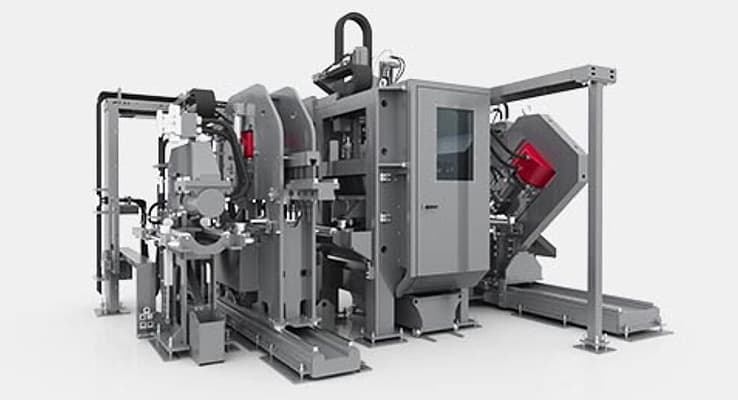

Beam Layout Welding Zone

D3 Touch from Welding Alloys allows you to control your welding process and tools using touch screens. Welding Alloys has integrated new technology into all Welding Alloys machinery, increasing performance and accuracy. This technology enhances precision engineering mechanics, resulting in maximum performance for our welding machines.

.jpg)